Khám phá xu hướng

Hơn 300+ bài viết xu hướng sẽ có ích cho bạn

Năng lượng

Solving Cell Dimensional Changes and Cell Breathing in Lithium Solid-State Batteries

04/07/2024

04/07/2024

Traditional liquid battery configurations, such as lithium-ion batteries (LIBs), can generate high amounts of pressure due to the swelling of electrodes and gas generation. Low pressures are considered desirable for battery systems as the cell pressure is transferred to the module and pack frame. Large forces, derived from these pressures, can lead to deformation of the battery frame and battery failure.

Heavier frames can be used to accommodate these pressures, but the added weight of the frame can sacrifice performance, especially in products like electric vehicles. All solid-state batteries (ASSBs) are designed with solid materials (devoid of any liquid component) and will mitigate some pressure concerns as they do not have the same swelling and gas generation issues as traditional liquid batteries. However, both LIBs and ASSBs will benefit from cell breathing solutions.

Battery Cell Dimensional Changes and Cell Breathing

Batteries that utilize lithium are vulnerable to cell dimensional changes during charging and discharging, where one electrode is expanding while the other is contracting. A battery cell can be exposed to significant degrees of expansion depending on the materials, for example, lithium alloys that utilize silicon in the anode are subjected to significant volume changes. These volume changes can decrease functionality at the particle level, electrode, and SEI layer. Problematic volumetric changes can also occur when utilizing lithium metal anodes as their cycling produces dendrite formation.1,2

The detrimental effects of cell dimensional changes include:

• Diminished energy density

• Reduced Cycle Life

• Increase in Impedance

• Safety Concerns

Thus, cell dimensional changes need to be a top priority for manufacturers when designing battery systems.

Lithium Foil Variation and Considerations

Lithium foils perform differently under varying pressures, capacity fade, dimensional changes and electrolyte sensitivity. Key variations in lithium foils include thickness (where thinner is usually better), deposition method, and coatings and pre-treatment of lithium. Another key variation involves the underlying composition seen in doped lithium and lithium alloys, which provides better capacity retention. Commonly doped and alloyed elements are In, Sn, Zn, Si, Al, Ag, and Mg.1,2

Compressive Loads and Requirements

The majority of the current ASSB designs require compressive loads 5x – 200x that of Li-ion batteries. This dramatic increase in compressive load requirement will add to the cost of manufacturing and increase the volume and weight of the system. Therefore, there is an urgent need for solutions to cell breathing and volume expansion issues for ASSBs.1,2

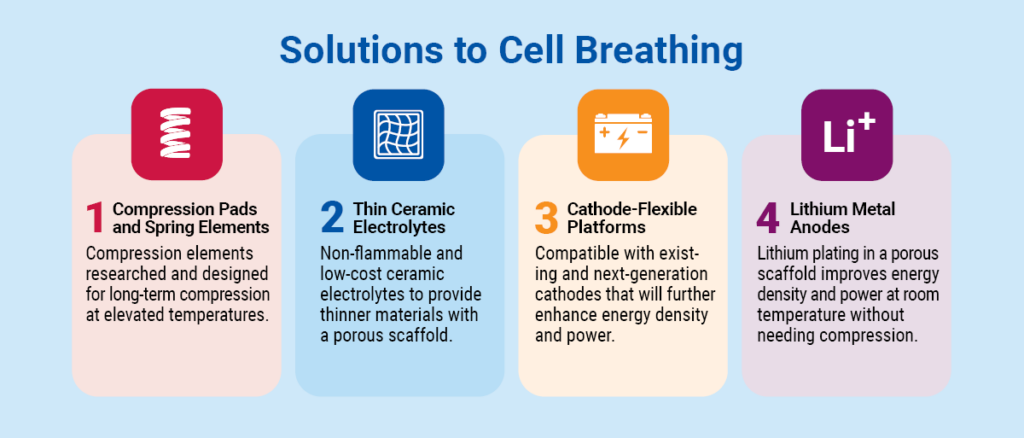

Solutions to Cell Breathing

The battery market is still researching solutions to solve cell dimensional changes and cell breathing, however, there are several promising innovations that can help address these concerns. Innovations and proposed solutions for cell dimensional changes and cell breathing include compression pads and spring elements, thin ceramic electrolytes, lithium metal anodes and cathode-flexible platforms.

Chia sẻ

Chia sẻ